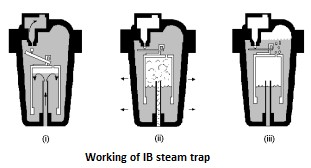

Primed at initial start-up to make it work properly. The accompanying sketch below shows the constructional details of an Inverted Bucket Trap.

During start-up air is vented through a bleed hole in the top of the bucket into the return line.

Inverted bucket steam trap animation. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Since the Armstrong Inverted Bucket Steam Trap was brought to market in 1911 the energy-saving performance of steam traps applying the inverted bucket engin. Operation and description of an Armstrong Inverted Bucket Steam TrapThe inverted bucket is the most reliable steam trap operating principle known.

Inverted Bucket Steam Trap. Inverted Bucket Steam Trap. As mentioned in my previous post the inverted bucket steam trap is a mechanical trap classified as a density operated steam trap which operates on the difference in density between steam and water.

The accompanying sketch below shows the constructional details of an Inverted Bucket Trap. As the name implies the working portion of the Trap consists of an Inverted. In inverted bucket steam traps the bucket within the trap is attached to a lever that opens and closes the trap valve in response to the buckets motion.

When steam or air flows into the underside of the inverted bucket and condensate surrounds it on the outside the steam causes the bucket to become buoyant and rise. Inverted bucket steam trap must be filled with water ie. Primed at initial start-up to make it work properly.

Also in low load or superheat conditions the trap may also need to be primed. During start-up air is vented through a bleed hole in the top of the bucket into the return line. Inverted bucket steam trap Mechanical steam traps The inverted bucket steam trap is shown in Figure.

As its name implies the mechanism consists of an inverted bucket that is connected by a lever to a Valve. A necessary a part of the trap is that the little air vent hole within the top of the bucket. Inverted bucket steam trap.

The inverted bucket steam trap is shown in Figure 1133. As its name implies the mechanism consists of an inverted bucket which is attached by a lever to a Valve. An essential part of the trap is the small air vent hole in the top of the bucket.

Figure 1133 shows the method of operation. Working principle of inverted type steam trap. Working principle of inverted type steam trap.

Check out these youtube videos on various aspects of steam traps such as their types assembly parts and operation. Inverted Bucket Steam Trap Tutorial Video by Affiliated Steam. Bimetallic Steam Traps Operation Video by Spirax Sarco.

Delta Venturi Orifice Steam Trap Animation. For pressures to 1 540 psig 105 barg. Armstrongs 401-SH501-SH Series inverted bucket superheat trap line is made for overcoming the difficult combination of superheat and high pressurelow load service.

To survive this most severe steam service Armstrong created an inverted bucket trap with a unique accumulation chamber. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Back to Basics - Steam Traps 101 Author.

Steam Trap Basics Keywords. Steam trap basics Created Date. Any steam system to keep efficiency high and to keep damaging water hammer and erosion to a minimum.

Sizing Superheat Loads to Traps The condensate load to a trap used on superheat will vary widely from severe start-up loads to virtually no load during operation. Consequently this is a demanding application for any steam trap. The Industrial Valve Training Course also includes a detailed coverage on Inverted Bucket Steam Trap Float Steam Trap Thermodynamic Steam Trap and Thermostatic Steam Trap Working.

The primary focus on Valve Animation Graphic in the Industrial Valve Training Program helps in very clearly understanding Valve Maintenance Procedures Valve. Capacities to 20 000 lbhr 9 072 kghr The most reliable steam trap known-the inverted bucket-provides efficient condensate drainage of virtually all types of steam-using equipment. Put the inverted bucket to work in a tough cast iron package and you have the best of both worlds.

All steam traps have the same objective. Pass condensate but trap steam Water steam trap preferences vary While steam is the same around the world there are interesting preferences for one type of trap over another in different countries this tends to reinforce the conclusion. The Anatomy of the IB.

Uses production techniques to look inside the inverted bucket steam trap. This videotape uses both cell animation and an operating glass-bodied model of an inverted bucket steam trap to show its components and observe its performance. Guidelines for Unit Heater Efficiency.

The first steam trap to make an appearance was a bucket type steam trap developed in the first half of the 1800s. The types developed in the early years of steam traps were a metal expansion type in the 1860s then an impulse type quite a bit later in the 1930s and finally in the 1940s the disc type with which we are all familiar.