Most velocity-based meters have an adjustment vane for calibrating the meter to the required accuracy. Either one does the same thing.

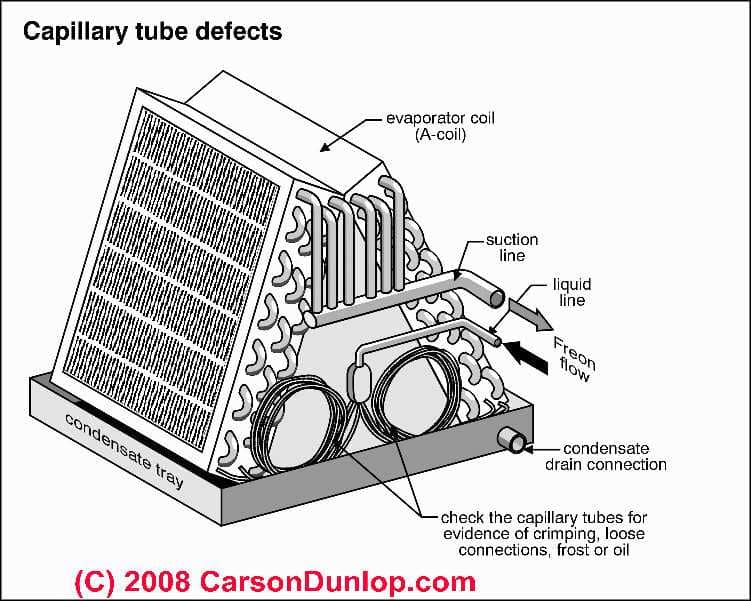

The capillary tube is commonly used as a systems metering device because of its simplicity and low cost.

Types of metering devices. What are 4 types of metering devices. There are several metering devices in a typical system including the thermostatic expansion valve TEV or TXV automatic expansion valves electronically-governed expansion valves balanced port TEVs superheat and multi-circuited TEVs and evaporators. The metering device is located after the condenser coil.

There are two kinds of metering devices thermal expansion valves TXV and capillary tubes. Either one does the same thing. They lower the high-pressure liquid pressure by forcing it through a small hole or nozzle.

What is the primary function of all metering devices. To provide refrigerant to the evaporator in a condition essential for efficient. Several types of meters measure water flow velocity including jet meters single-jet and multi-jet turbine meters propeller meters and magnetic flow meters commonly referred to as mag meters.

Most velocity-based meters have an adjustment vane for calibrating the meter to the required accuracy. For many comfort applications however other refrigerant or even another type of chemical used. Such valves say offset valves.

Cross charged valves are also used for commercial work where the constant overheating is not mandatory. 50F saturation temperature in. The following are among the common types of metering systems used for liquid filers.

Turbine Meters These are the conventional options for metering in liquid fillers as they have a high level of accuracy and they maintain their reliability throughout their useful life provided that you install a proven calibrated system at regular intervals through their length in your production process. What is a Metering Device Specific Types of Metering Devices used in HVAC Refrigeration. Thermostatic Expansion Valve - Also referred to as the TEV or TXV for short.

The thermostatic expansion valve is used in many HVAC applications including use in. The capillary tube is commonly used as a systems metering device because of its simplicity and low cost. A more sophisticated type of metering device is the thermal expansion valve TXV or TEV.

What are three types of metering devices. There are three main types of metering devices. Thermal Expansion Valve TXV.

I have been searching trying to find the other 5 metering devices. I already know enough about cap tubes and tx valves for the amount of time ive been in refrigeration. So far Ive done it for roughly 6 months and I have not yet gon to TAFE.

I would like to learn as much as possible or at least 6 months worth so that Im not left to catch up. Type of metering device that can be used in multiple flooded evaporator applications - low side float - high side float - short tube restrictor - capillary tube. There are several metering devices in a typical system including the thermostatic expansion valve TEV or TXV automatic expansion valves electronically-governed expansion valves balanced port TEVs superheat and multi-circuited TEVs and evaporators.

The two basic functions of a metering device include. Feeding refrigerant to the evaporator. Accordingly what are three types of metering devices.

There are three main types of metering devices. Thermal Expansion Valve TXV what is the metering device. The metering device is responsible for feeding the proper amount of refrigerant.

HVAC Metering Device Types- TXV Piston Capillary Tubes - YouTube. Types of mass flow meter. How does a flow meter work.

Flowmeter consists of devices such as transducer and transmitter the transducer will sense the fluid that passes through the primary device. The transmitter will receive a signal from the transducer so the transducer changes this signal into a. There are two kinds of metering devices thermal expansion valves TXV and capillary tubes.

Either one does the same thing. They lower the high-pressure liquid pressure by forcing it through a small hole or nozzle. The metering device acts like your garden hose nozzle turning a steady stream of liquid into sprayed droplets.

A more sophisticated type of metering device is the thermal expansion valve TXV or TEV. The top of the TXV has a sensing bulb that is attached to the suction line the line connecting the evaporator with the compressor. The sensing bulb contains a substance usually the same as the systems refrigerant.

The metering device is located after the condenser coil. There are two kinds of metering devices thermal expansion valves TXV and capillary tubes. Either one does the same thing.

They lower the high-pressure liquid pressure by forcing it through a small hole or nozzle. Different types of metering devices have different ways of charging. A thermostatic expansion valve TXV is charged to the subcooling of the liquid line leaving the condenser.

A fixed orifice is charged to the superheat of the suction line leaving the evaporator. The metering device is responsible for feeding the proper amount of refrigerant to the evaporator coil. It is also know as the expansion device.

The basic requirement of a reciprocating fuel metering system is the same regardless of the type of system used or the model engine on which the equipment is installed. It must meter fuel proportionately to air to establish the proper fuelair mixture ratio for the engine at all speeds and altitudes at which the engine may be operated. Several types of device metering such as star-wheel feed ro-tating bottom plate auger-type loose-fitting auger edge-cell vertical rotor and belt-type metering device 3.

Auger type metering device has a better performance than other types in terms of easy to control of its rotation and able.